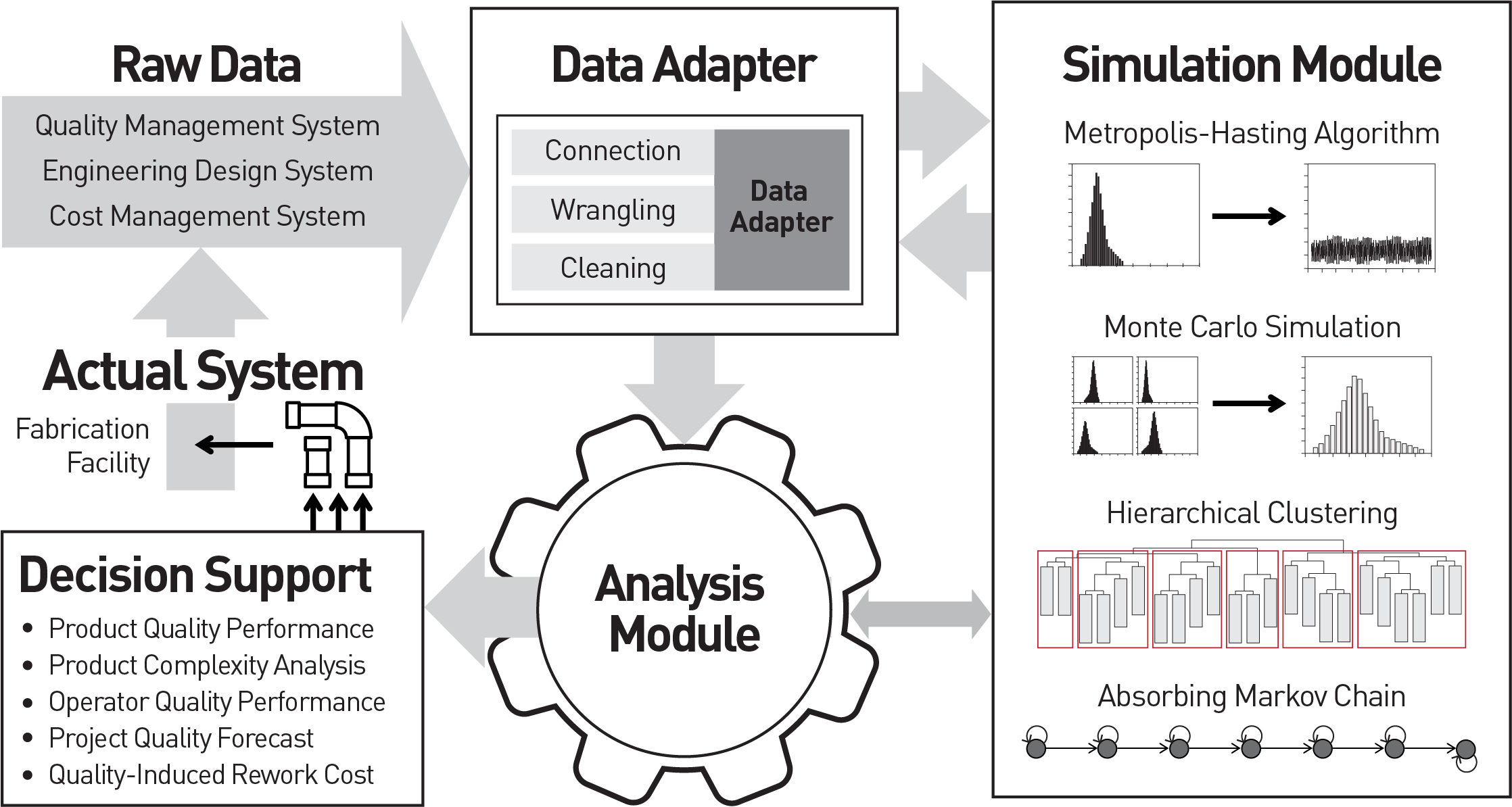

Framework of simulation-based analytics for quality-associated decision support system.

Computer-based quality management systems have been widely implemented throughout the construction industry as per the requirement of the International Organization for Standardization (ISO) 9000. Although these systems have facilitated the collection of vast amounts of quality management data, conversion of this data into usable information remains challenging for many practitioners. Automated, data-driven quality management systems, which facilitate the transformation of data into usable information, are often implemented to enhance decision-making processes. However, for a data-driven quality management system to be successful, it must accurately estimate process uncertainty. Integration of accurate, reliable, and straightforward approaches that measure uncertainty of inspection processes are instrumental for the successful implementation of automated, data-driven quality management systems.

This research has addressed these limitations by exploring and adapting Bayesian inference-based analytical solution and Markov Chain Monte Carlo (MCMC)-based numerical solution for updating quality-associated decision-support systems in real-time. Using these accurate and reliable inputs, this research further develops novel, analytically-based approaches to improve the functionality of traditional pipe welding quality management systems.

Industrial Contributions:

- Development of a simulation-based analytics decision-support system to enhance several quality-associated decision-support processes, including project quality performance forecasting, operator quality performance measurement, construction product complexity determination, and rework cost management. Notably, the proposed system can be generalized for all nonconforming quality-related products across multiple industries.

- This research also creates meaningful simulation results, which assist practitioners in performing quality and rework cost risk analyses during both the planning and execution phases of construction.

Associated Publications:

- Ji W and AbouRizk S. "A data-driven simulation model for quality-induced rework cost estimation and control using absorbing Markov chains." Journal of Construction Engineering and Management [in press].

- Ji W, AbouRizk S, Zaïane OR, and Li Y. (2018). "Complexity analysis approach for prefabricated construction products using uncertain data clustering." Journal of Construction Engineering and Management, 144(8): 04018063.

- Ji W and AbouRizk S. (2018) "Simulation-based analytics for quality control decision support: a pipe welding case study." Journal of Computing in Civil Engineering, 32(3): 05018002.

- Ji W and AbouRizk S. (2017) "Credible interval estimation for fraction nonconforming: analytical and numerical solutions." Automation in Construction, 83(2017): 56-67.

Investigator: Wenying Ji

Project: Simulation-Based Analytics for Industrial Construction