Powered by 3-D printing and a desire to help during the COVID-19 pandemic, a University of Alberta lab technician has been busy creating mask straps and face shields—and helping community causes along the way.

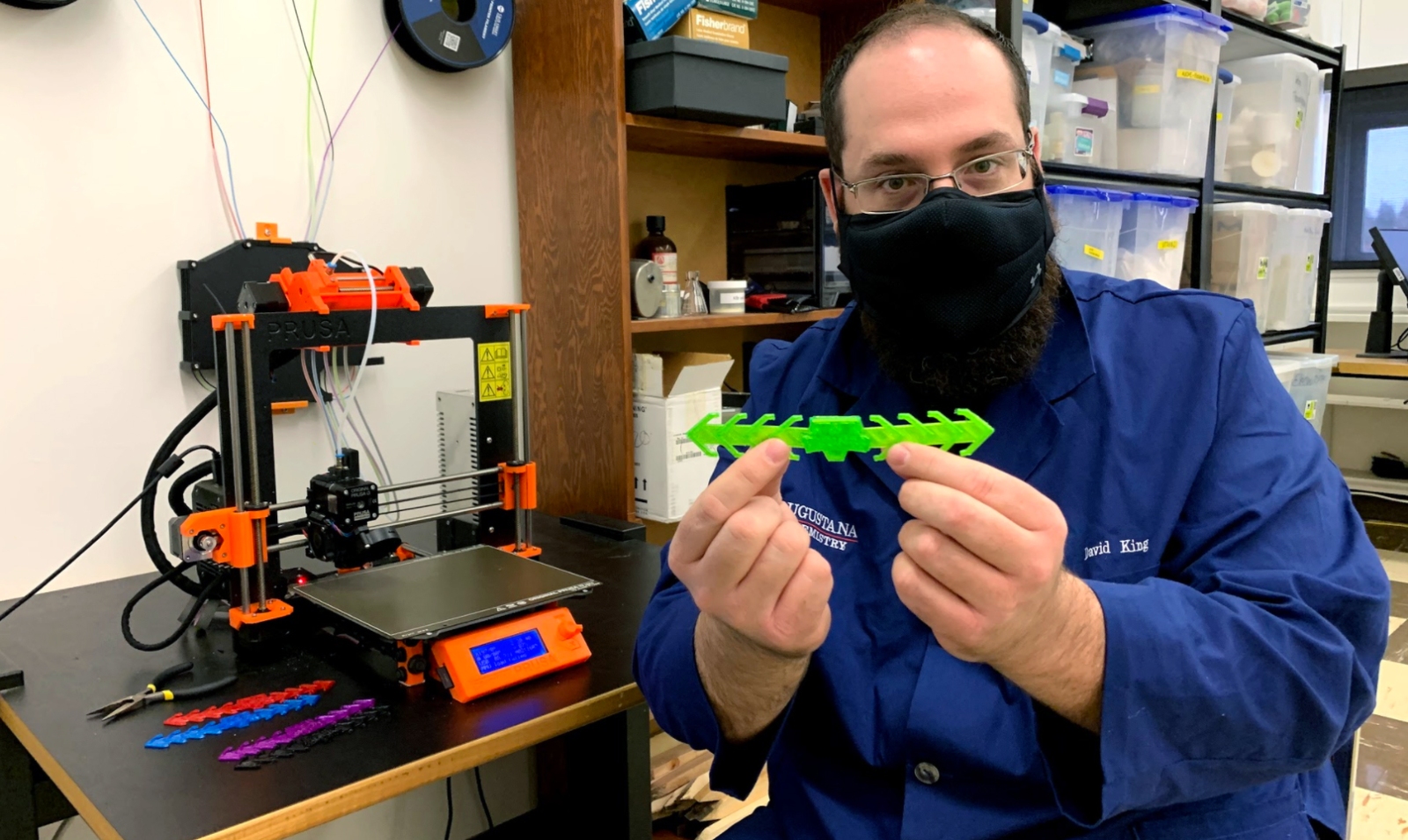

Viking Ear Savers, soft plastic mask straps created through a 3-D printing service on Augustana Campus by technician David King, are being used by diagnostic imaging technologists at the University of Alberta Hospital.

“While we didn’t cure anything, we helped the people on the front line,” said King, who works in the Augustana Department of Chemistry and is also a graduate of the Camrose-based campus.

“People say that necessity is the mother of invention, but for me, it’s been more simplistic than that: I really just wanted to help,” he added.

“I also wanted to show that we’re not just a chemistry department with a 3-D printer—it’s not something that we have just to benefit us.”

He began crafting a design for the pain-free straps—named for the campus sports teams—after the pandemic struck, when hospital workers first expressed a need for “ear savers” because wearing surgical masks on their shifts had rubbed their ears raw, almost to the point of bleeding.

Using flexible rubbery material, King fashioned the stretchy, one-piece strap to be a more comfortable alternative to elastics on face masks. The invention proved popular, with about 90 pairs donated to health-care workers.

Contributing to charitable causes

The project is also helping charity, as a Camrose group offers the ear savers along with their homemade masks for donations to muscular dystrophy research and the Children's Wish Foundation; to date, King’s invention has contributed to raising $25,000, and he's busy printing out 1,000 straps for the causes.

King has kept the high-tech printers humming with other projects, too—particularly for his campus community.

Mindful of students, faculty and staff returning to Augustana Campus for required in-person labs, King came up with an inexpensively made, partly removable face shield of thin, flexible plastic that can be cleaned between uses and comes with a comfortable head strap to avoid soreness and tangled hair.

“One of the big issues students fear with in-person class is will they be safe, so the more positive things you can place in the labs, the more comfortable they’ll be.”

A total of 70 face shields were printed off for use by students, instructors and staff in chemistry and biology, and King expects to print off more next term as well. He also designed and printed off tiny holders to keep plastic panels in place between lab stations.

So far, the wraparound shield is getting top marks from everyone using them, he added.

“They love them because it eliminates the need for safety glasses, which fog up when you wear a regular mask.”

New plans

He’s also created a printable 3-D design—still under development—for protective goggles that can be printed off as a single piece, along with a printable strap. While it’s not yet perfected, the design offers protection against droplets and could be used to print off a pair of goggles in a pinch, using soft plastic materials that can easily be ordered online, King said.

“I started by literally measuring my face and then tried to think of materials that people might be able to access. I drew the 3-D image and needed three prototypes to get the design where I liked it.”

Using Canadian suppliers for his materials, he hopes to have a good prototype ready for safety certification next summer, and plans to continue using his skills to help however he can.

“Being a part of Augustana is so ingrained into me that I want to give back every chance I get. And part of being at Augustana means that we don’t just benefit ourselves; we benefit the community around us.

“It blows my mind that something I made is out there helping people, and it makes me want to do more.”

Great ideas change the world, but ideas need a push forward. At the University of Alberta, we know that push has never been more important as we do our part to rebuild Alberta and keep doors of opportunity open to all. We're making research discoveries. We’re cultivating entrepreneurs. And we’re giving our students the knowledge and skills they need to turn today's ideas into tomorrow's innovations. Read more stories about U of A innovators.