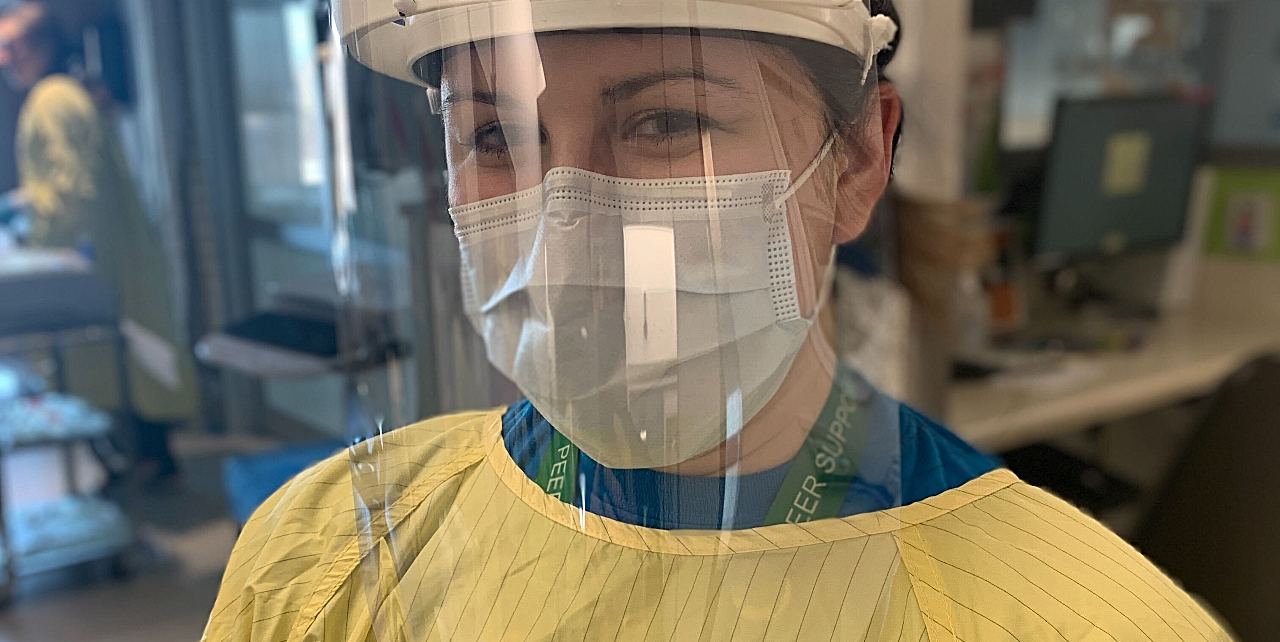

A group of University of Alberta clinicians, engineers and designers are working with Alberta Health Services (AHS) to create up to 2,000 3-D printed face shields for use in Alberta's hospitals as stocks of personal protective equipment (PPE) continue to dwindle worldwide.

"Our team is working to proactively design and manufacture PPE that is reusable, safe and comfortable, and that meets Health Canada's standards," said Charles Larson, a U of A clinical assistant professor in pediatrics and pediatric cardiac intensivist at the Stollery Children's Hospital.

"We are first concentrating on face shields. Without them, droplets can both penetrate the eyes' mucus membranes and can sit on the skin to be spread the next time a person touches their face."

With the number of COVID-19 cases expected to peak in Alberta in May, the team is racing to test and produce the face shields to aid health-care workers. An initial batch has already been piloted at the U of A Hospital for feedback from health-care workers ahead of final production.

"We're not trying to replace what we have and what is proven. What we're trying to do is create a product that we could use if we run out of PPE and we start seeing shortages the same way that other jurisdictions have," said Larson.

"There have been a lot of scenarios around the world where there have been more health-care workers infected in some hospitals than there are patients, which creates a real problem because that severely reduces capacity if they can't work. We can't afford to get health-care workers sick."

The team, made up of members of the U of A's Faculty of Medicine & Dentistry Academic Technologies unit, is working with AHS to come up with new protocols to safely use and clean the reusable face shields. It has also rushed to receive approval from Health Canada to manufacture the devices-a process that was completed in a single day in light of the current crisis.

The team is now working with several partners including the Elko Engineering Garage, an Engineering at Alberta maker space, and Karma Machining & Manufacturing to produce the face shields, beginning this week.

The team is also employing the help of private citizens and charitable groups who have volunteered the use of their 3-D printers.

"It's incredible and so very generous of them. There are people all over Edmonton who are keen to do this work," said Larson. "And according to Health Canada, as long as there's a centralized area to do quality control and to take a look at these products, anyone can print medical devices and send them in. So this is completely legitimate and makes a lot of sense in a crisis situation."

The material cost of producing each face shield is about $12. While the early prototypes have been funded out-of-pocket by the team, it has created a GoFundMe page to help finance the cost when production begins in earnest. Money raised through the initiative will be administered by the University Hospital Foundation.

If AHS doesn't end up immediately needing the face shields when production begins, Larson said they will instead be rerouted to Alberta nursing homes in need of PPE to protect staff and prevent the spread of COVID-19 among elderly Albertans who remain at higher risk.

While the primary focus is on producing reusable face shields, the team is also working to build other devices to assist during the crisis, including clear acrylic boxes that can be put over patients when taking out their breathing tubes to minimize aerosols going into the room. They plan on publishing their work for others to use as a template.