Dylan Brenneis, '16 BSc(MechEng), has unfinished robot business. Years ago, he started building an automatic breakfast-maker, so his morning alarm would trigger a robot to make toast and serve it with peanut butter. But then he moved and had to dismantle it. Bye-bye, robot.

So when New Trail asked the master's student to show us how to make one using household junk, he was not only game, he was enthusiastic. He says a robot, as opposed to a machine, has a brain - it makes decisions based on input. Unlike artificial intelligence, however, it's not a complex brain. "The robot is kind of your middle point between machine and intelligence," says Brenneis.The principles behind building a robot, he says, boil down to having a small motor, a big idea and a lot of glue.

Brenneis started by stripping a DVD player for parts. Inside, he found a disc support, motors, and magnets. He kept some screws, a hunk of plastic ribbon cable and an AV port. "This," Brenneis said, preparing to cut the motor wires, "is when you decide this DVD player is no longer going to work."

Here how his build unfolded; if you want to build this robot here are some detailed instructions. And we'd love to hear how yours works.

The bumper and the "brain"

A robot needs a mechanism - a brain - to trigger an action based on input. This robot's mechanism is a bumper that slides to close a switch. The action it triggers is to reverse direction based on the input: striking a wall. To make this happen, Brenneis devised a sliding bumper of Popsicle sticks and lots of glue. His double layer of sticks looked a bit like the letter H, with braces for support.

The chassis

"With frame material, you're trading off between something that's lightweight and something that's strong," Brenneis said. Corrugated cardboard is ideal; unrolled pop cans are also strong and malleable. He opted for a 16 x 48 cm rectangle of cereal box cardboard, its ends folded into isosceles triangles to create struts.

The mechanics

It was just a few screws, tiny magnets, bits of wire and a paper-clip, but the bumper mechanics were the trickiest element to execute. Wire-hanger guides secured the bumper to the chassis, allowing the bumper to slide horizontally. Screws and magnets limited how far it could slide. And a heavy-duty paper-clip, twisted into a series of loops and whorls, became a switch that controlled the electric current.

The electrical

For the electrical infrastructure, Brenneis soldered wires to two paper-clips and two metal tacks. The real genius, though, was the trio of foil contact surfaces. One surface would be electrically charged, the others would be grounded. Why genius? Because the combination of foil surfaces and metal tacks (which became part of the electrical switch) were what reversed the motor's direction.

The motor

A robot without a motor isn't a robot. But motors are easy to cannibalize, Brenneis said. "Take apart just about any electronic thing with moving parts and there's a motor in there." The challenge was the linkage - the mechanism that translates the motor's spin into robot action. Brenneis used an elastic band that connected the motor to a drivetrain made of a pair of glued-together bottle lids.

The wheels

R2-D2 was a wheeled robot and so is this one. Luckily, jar lids are plentiful and the mechanics are easy. "Translating rotational motion to another rotational motion is the simplest thing you can do with a motor," Brenneis said. His robot's undercarriage used pieces of a drinking straw for bearings, pencils for axles, elastics for tread and glue all over.

The power source

With a twist of wires and a bit of duct tape, it was time to see if he had hooked things up correctly. He connected thumbtack wires to the motor, and paper-clip wires to the battery terminals. When he attached the paper-clips to the foil surfaces, the motor ran. And when he pressed on the bumper, it slid the electrical switch, which reversed the motor's direction.

The personality

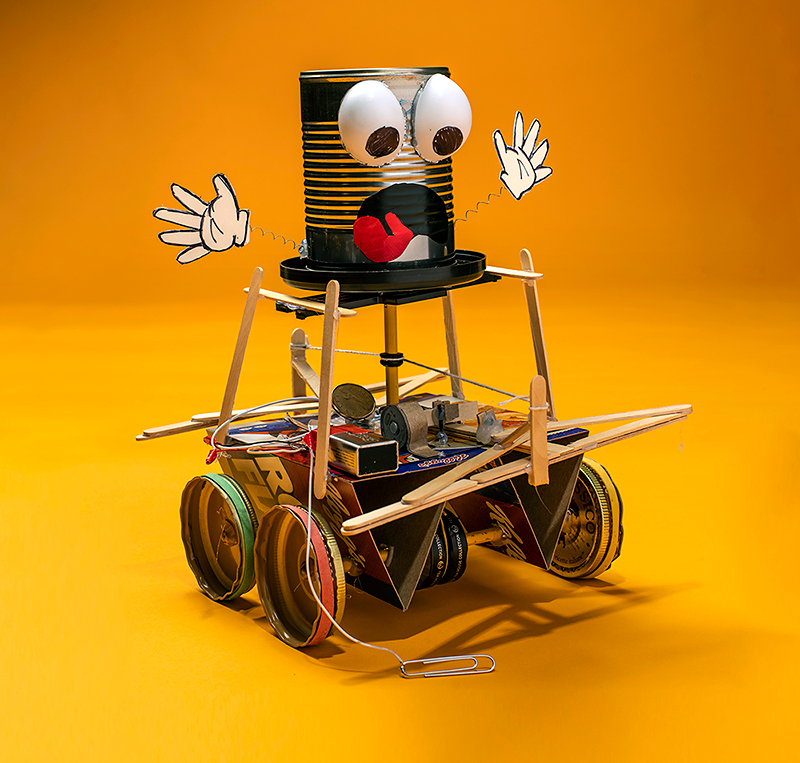

Now to make it lovable. Brenneis built in some character with a tin can body, Ping-Pong eyeballs and sproingy arms. The body sat atop an elevated platform made from a plastic lid and the disc support. But there was one more twist - a piece of string stretching between bumpers that turned the platform, ensuring the robot always faced forward in its travels.

The robot!

Brenneis steadied the robot for its first voyage. He carefully connected the paper-clips to the tin foil … and it worked! Wheels spinning, arms waving, the robot took off, hit the wall - then, just as the engineer had planned, it reversed direction and came back, facing forward. "This," said our clearly pumped mechanic, "is the first time that I've planned something out completely on paper and it worked. It actually worked!" And that unfinished robot business? Mission accomplished.

We at New Trail welcome your comments. Robust debate and criticism are encouraged, provided it is respectful. We reserve the right to reject comments, images or links that attack ethnicity, nationality, religion, gender or sexual orientation; that include offensive language, threats, spam; are fraudulent or defamatory; infringe on copyright or trademarks; and that just generally aren’t very nice. Discussion is monitored and violation of these guidelines will result in comments being disabled.