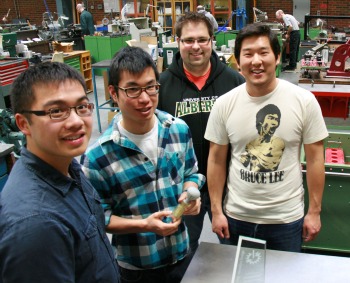

Mechanical engineering (biomedical) students Jordan Leung, Andrew Kan, Kenton Hamaluik and Allen Feng won the innovative design award at the Western Engineering Competition and Canadian Engineering Competition, with their design for a craniostomy and ventriculostomy drill (below).

Edmonton-A group of mechanical engineering (biomedical) students has won a national award for their innovative design of a device that could improve patient care in urgent medical cases.

Kenton Hamaluik, Andrew Kan, Jordan Leung and Allen Feng designed a craniostomy and ventriculostomy drill for Edmonton neurosurgeon Dr. Richard Fox, as an assignment for their Mechanical Engineering 460 senior design course. Earlier this year, the students took the design to the Western Engineering Competition and won the innovative design award there. Next, they won the national award for innovative design at the Canadian Engineering Competition in Montreal.

The team's design addresses specific challenges their client thought could be eliminated. Fox explained to the students that surgeons in operating rooms have access to power tools but in emergency rooms and at bedside, doctors use manual drills to perform craniostomy and ventriculostomy procedures. The problem with those drills, Fox told the students, has a lot to do with control of the drill bit.

Hand-cranked drills that resemble eggbeaters and goose-neck drills can present a problem with drilling direction and the bit itself sometimes "walks" across the surface rather than penetrating it. These drills also represent a risk to patients because there is no depth gauge.

"One of the main problems is that there isn't a safety depth stop to prevent what the surgeons call 'plunging'-uncontrolled drilling through the skull and into the brain," said Leung.

"At the bedside and in the ER they are restricted to manual drills, and going to the operating room usually takes a lot of time," added Kan. "This is a time sensitive issue so you what to get the procedure done as quickly as possible."

The design team solved that problem with a setting feature that only allows the drill bit to penetrate to pre-set depths. Doctors can and more depth as the procedure requires. What's more, the drill is designed to do both procedures: one requires a hole to be drilled perpendicular to the skull, while the other requires an angled approach. The drill the students designed separates, giving doctors the choice of using a flat or an angled face and the ability to perform either procedure with one tool.

The course gives students experience working in teams and with clients, applying knowledge they've learned in the classroom to a real-world problem. It also helps them develop key skills like communication. Taking the project into competitions added a new dimension, the team says.

At the national competition the team was required to conduct two 20 minute presentations and hold question-and-answer sessions with judges.

The four are now looking into patenting the device. And two of the team members, Leung and Feng, are now applying to medical schools.

"The communication and critical thinking skills developed throughout my engineering undergraduate experience will help in the field of medicine," said Leung. The approach to patient care is also becoming more interdisciplinary. Thus, the teamwork skills gained through engineering will be important."

"The one thing that engineering has given me, above all else, is a different perspective," said Feng. "As an engineer, I think that I'll be able to see problems differently and create unique solutions to novel problems."