Science and Technology

Donor support helps push new mask research into the end game

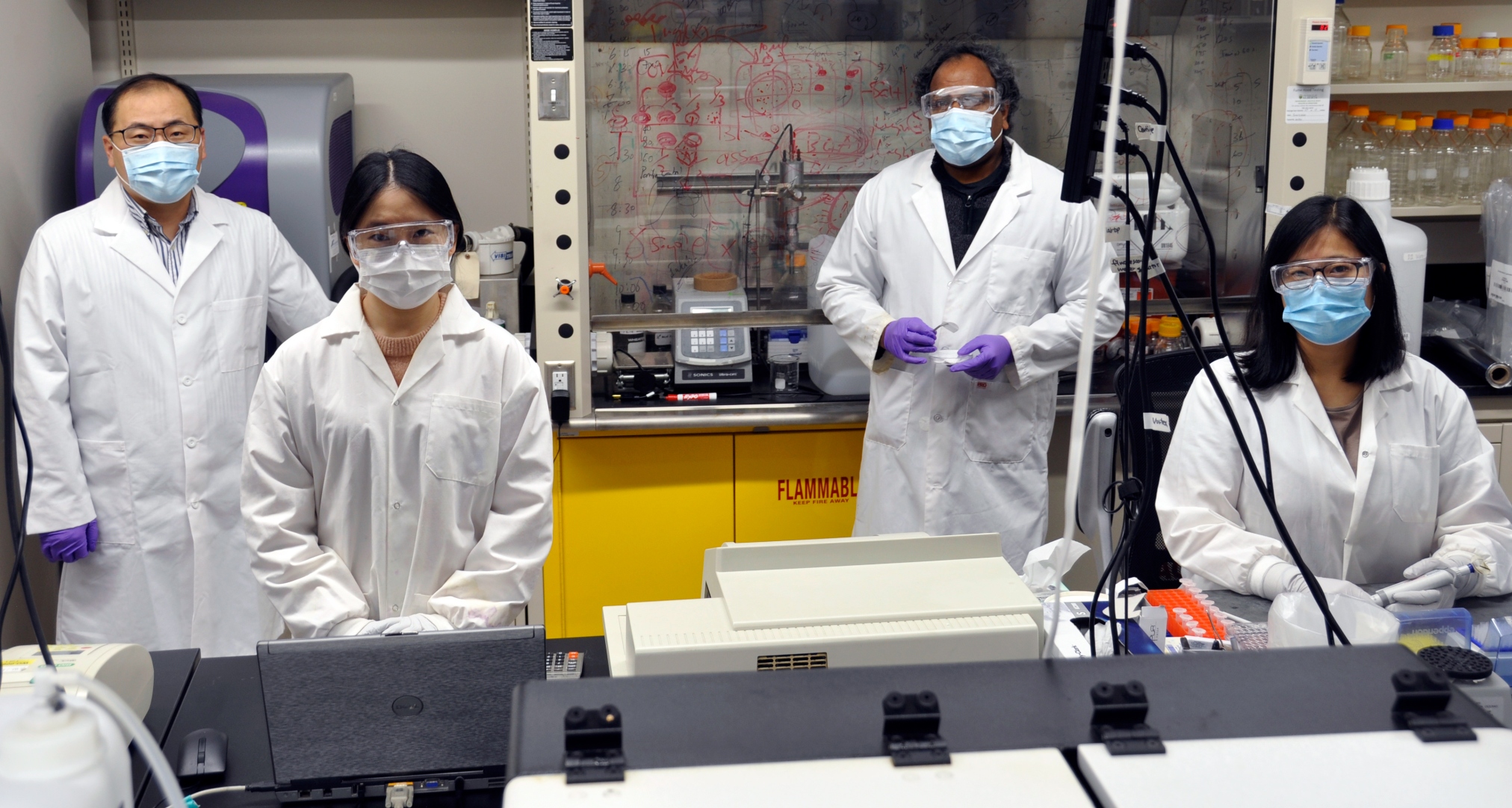

Dr. Choi (left) and his lab team. (Photo: Michael Brown)

Hyo-Jick Choi, assistant professor in the Faculty of Engineering’s Department of Chemical & Materials Engineering, says that the $35,000 in funding came at just the right time.

“I started working on face-mask technologies to prepare for pandemic diseases in 2015, and the hardest part was securing funding for my research because people weren’t worried about a pandemic at that time,” Choi said. “Then at the beginning of the pandemic it was also hard to find funding … there was no common understanding that face masks can actually help to prevent the spread of the disease. So for me, the funding from the COVID-19 and Emerging Pathogens Fund was really important.”

The COVID-19 and Emerging Pathogens Fund was supported primarily through public donations. A month-long U of A fundraising campaign last May for COVID-19 research, using the global movement Giving Tuesday NOW as a launch pad, received more than $200,000 from donors—including foundation partners and a few matching gifts. The funds were then directed through the Li Ka Shing Institute of Virology towards six new COVID-19 related projects across three faculties, including Choi’s project in Engineering.

The salt-coated mask filter

As reported last October, Choi, head of the Sustainable Engineering and Drug Delivery Design (SEƎD) lab, developed the idea of an antiviral, antibacterial filter for face masks that uses salt recrystallization to destroy airborne pathogens when they come in contact with the mask. Viruses are often transmitted through the air in small and large moist droplets, such as in a cough or a sneeze. When these droplets come into contact with the salt filter, they are absorbed by the salt coating. When the salt dries, reforming into solid salt crystals, the recrystallization effectively tears the pathogens apart.

Though traditional face masks protect wearers from exposure to pathogens in droplets, the mask itself can become an infectious agent as a result of the droplets caught within it, and the improper removal of the mask can end up spreading the virus the mask was meant to protect against. The benefit of Choi’s approach is that the droplets, and any pathogens contained within them, are destroyed, making the masks much safer to use.

Expanding the technology

In addition to keeping his work with the salt-coated filters moving forward—including doubling his efforts to secure funding and manufacturing partners from the private sector—the funding has allowed Choi and his team to expand their research into new applications of the salt-based antiviral technology.

“The funding has allowed us to launch another project, which is the development of antimicrobial face shields and other PPE products, such as gowns, using a photo-responsive spray,” Choi says.

“We wanted to develop antimicrobial technology that can be easily implemented,” he explained. “So the idea is that you spray a surface and just use it. We can transform regular face masks into antimicrobial masks without having to modify any manufacturing facilities.”

Choi also expects to publish a research paper on this new approach in the next few months, and will continue to look for opportunities to expand production of the salt-coated filter mask.

“Funding is one of the critical components of our research. It is the catalyst to make it happen,” he says. “We can come up with an idea, we can create the solution, but the funding is the fuel.”