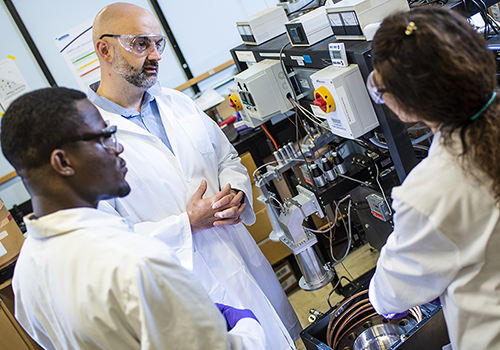

Dr. David Bressler (centre) checks on research in his lab with graduate student Samuel Koranteng (left) and postdoctoral fellow Maryam Hawk. Bressler's biofuel research is being commercialized at a plant in Ontario.

The world's appetite for energy is growing.

While the population is set to creep toward nine billion by 2040, the energy demand is estimated to grow by more than 25 per cent, requiring an investment of $2 trillion per year in new energy supplies, according to the International Energy Agency (IEA).

With so many people using energy for everything from vehicles and lighting to cell phones and food production, the world needs all the energy it can find. While coal and gas are still the world's top sources of energy, how do we satisfy our need for juice while addressing climate change?

There's no easy answer, no single answer and no quick answer, but one University of Alberta researcher is working to be part of a solution, and he's getting help from some big names.

Dr. David Bressler, a professor in the Faculty of Agricultural, Life & Environmental Sciences, is the science mind behind an advanced biofuel company that recently received a $4-million USinvestment from Lockheed Martin. The investment will help Forge Hydrocarbons Corporation build a $25-million demonstration manufacturing plant in Sombra, Ont. The facility is set to produce 30 million litres of renewable biofuel annually.

"The human race is under-energized," said Bressler. "The world will use any and all energy that is made, and that includes fossil fuels and renewable sources such as biofuel, hydro and geothermal. I can see there being a definite increase in renewable energy sources. And this is another step toward commercialization of an advanced renewable biofuel."

"We are impressed with Forge and its contributions to providing this advanced, renewable fuel technology to the global community," said Charles Bouchard, chief executive of Lockheed Martin Canada.

Forge Sombra, a subsidiary of Forge Hydrocarbons, will operate the plant. Site preparation and engineering designs are underway, and Forge hopes to be operational in late 2019.

From benchtop to boardroom

In 2004, Bressler invented a new way to convert lipids into hydrocarbons that are used as fuel: lipid-to-hydrocarbon (LTH) technology.

The first step is to heat waste and low value lipids (such as cooking oil, animal renderings and crop seed oil) with water at a high temperature. This creates fatty acids and glycerol. The glycerol is removed and the fatty acids are heated at more than 400 C until the oxygen within is released and the hydrocarbons are "cracked" to a range of hydrocarbon lengths. As a result, the process turns the acids into hydrocarbons that are separated into gasoline and diesel.

To date, to generate advanced hydrocarbon biofuels, petroleum companies have used hydrogen and a mineral catalyst to remove the oxygen, a process that's more expensive and with a higher carbon intensity than Bressler's patented LTH technology, and it requires cleaner feedstocks such as high-value canola or palm oil.

"We can use really dirty fuels like used cooking oil and animal renderings," said Bressler. "And our process leaves less of a carbon footprint because we do not require hydrogen, often generated from natural gas."

The result is a drop-in biofuel that doesn't need to be blended with petroleum-based fuel, the way ethanol does, and can produce renewable fuel with 90 per cent less greenhouse gases than conventional fuel. While scientifically this biofuel can be used as-is in a vehicle, the reality is that it will likely be blended into petroleum-based fuel, so less fossil fuels are used by consumers.

The Government of Canada requires that all transport fuels in Canada have two to four per cent biofuel in their mix. This means if you have a 60-litre fuel tank in your vehicle, you have 1.2-2.4 litres of biofuel and the rest is fossil fuels.

So what started as a research project in Bressler's lab turned into the university spin-off company, Forge Hydrocarbons, founded in 2012 and led by entrepreneur Tim Haig. TEC Edmonton handled and supported the commercialization of Bressler's technology.

In 2013, Bressler's team started refining the patented conversion process at Forge's pilot plant at the Edmonton Waste Management Centre in northeast Edmonton. That plant was scaled to pump out 200,000 litres per year - significantly less than the new Ontario plant is expected to produce.

In 2016, Forge received a $4.2-million grant from Sustainable Development Technology Canada, which only funds groundbreaking, economically viable products.

"It's a huge validation," said Bressler at the time. "It's capital investment. It's not a research project anymore."

This latest investment is not only another big step toward the commercialization of Bressler's LTH technology, but also a way to help achieve the federal government's clean fuel standard to reduce the country's greenhouse gas emissions by 30 megatons by the year 2030.

"We are truly excited to see the successful commissioning and operation of Plant 1 in Sombra," said Bressler. "If it gets anywhere close to meeting production and profit targets, there are numerous opportunities for major deployments of additional facilities across Canada and globally."